About us

We are a leading supplier for medical technology companies in the fields of traumatology and orthopedics.

In the field of traumatology and orthopaedics we manufacture a wide variety of products, including bone plates, screws, bone drills and countersinks, surgical instruments, screwdrivers and drill guides.

Why PTU ?

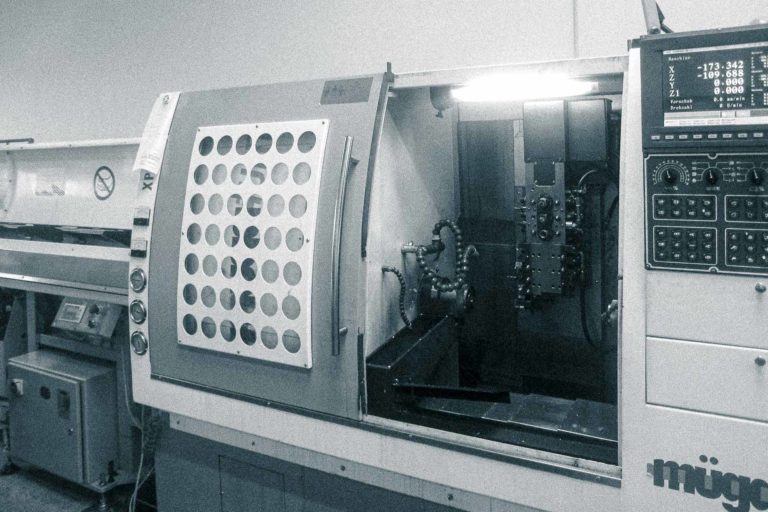

State of the art CNC manufacturing

10 x CNC sliding headstock lathes up to ø 38 mm,

7 x 5-axis CNC machining centers and

3 x 5-axis CNC grinding machines

Efficient CNC manufacturing

Manufacturing high-quality implants and instruments cost-efficiently through a great deal of know-how. Our international customers, including numerous well-known medical technology providers, have relied on this for many years..

Quality

Manufacturing maximum precision with maximum efficiency: As a responsible and reliable partner, we guarantee consistently high quality.

Consulting

From prototypes to series production: benefit from our know-how in medical CNC manufacturing.

CAD/CAM

For data exchange and design we work with Solidworks. With SolidCAM modules for 2.5D to 5X simultaneous Machining in milling and turning, we create efficient and process-safe CNC programs.

Precision

Optimized manufacturing processes ensure maximum precision. Our quality management documents and checks parts and samples employing validated 3D measuring machines, optical coordinate measuring machines and high-resolution microscopes.

Company History

We have been growing with our tasks and responsibilities. From the classic basement side business, we have developed into one of the region’s largest manufacturers of medical implants and instrumentation. We are proud of that.

What drives us? Our passion for state-of-the-art machining technology and precision, as well as the passion to manufacture perfect medical products.

2005

Production area 40sqm

2007

Production area 250sqm

2008

Production area 450 square meters

2016

2017

5 CNC sliding headstock lathes.

Production area 1500 square meters